By Roaul Drapeau

In a 1921 bombing test, U.S. Army Air Corps General Billy Mitchell’s airmen sank the former German battleship Ostfriesland. Although it took 65 bombs aimed at the huge, motionless ship to accomplish the task, the test challenged the primacy of battleships as an offensive weapon. U.S. war planners were already settling on the idea of precision strategic bombing as a way to capitalize on the potential of airpower and avoid the horror of trench warfare, which had been the hallmark of World War I on the Western Front. This meant eliminating an enemy’s ability to fight by destroying its manufacturing centers, transportation, and power infrastructure. However, strategic bombing required precision bombsights that would work from much higher altitudes and speeds than were then being designed into the next generation of bomber aircraft. It paved the way to the development of the now famous Norden bombsight.

Why the Norden Bombsight Was Initially Fraught with Troubles

The U.S. Navy’s Bureau of Ordnance (BuOrd) decided to develop such a precision bombsight, and in 1920 contracted with Carl L. Norden, a Dutch citizen and recent immigrant with a reputation as a clever designer of gyroscopically stabilized systems. Norden finished his masterpiece in 1931. Lieutenant Frederick Entwhistle, the Navy’s chief of bombsight development, called it revolutionary, and its design was good enough that it would be used throughout World War II and up to the Vietnam War.

To this day, a legend surrounds the accuracy of the Norden bombsight and the device’s role in the Allied victory in World War II. Mostly the result of intense self-promotion by Norden’s company, the legend is just that. The bombsight’s accuracy never met planners’ expectations. Nonetheless, practically every article about the bombsight in the popular media of the day referred to the claim that with the Norden design, bombardiers could hit a pickle barrel from 20,000 feet. To help foster the notion of accuracy, Norden used a clever Latin motto, “Cupa fiat melior muriae: per Norden obibit,” loosely translated as, “When better pickle barrels are built, Norden will hit them, too.” Actually, from that altitude, such a small object would be completely obscured by the bombsight’s crosshairs, so the idea of being that accurate is absurd.

Even for larger targets, though, the Norden’s accuracy never could have been as good as the strategic bombing doctrine needed it to be, considering the limited engineering and manufacturing capabilities of the time, unwise design choices, inherent errors in the mechanism itself, the complicated physics of bomb ballistics, the hazards of war operations, inadequate training, and poor reliability.

The bombsight’s reputation was also tarnished and costs raised by unnecessary security precautions, unseemly interservice squabbles, and the wasteful policies of the armed services using it. However, because of the great secrecy surrounding its specifications and performance, Washington’s desire to boost public morale, and Norden’s publicists wanting to promote the superiority of their monopoly product, the truth was hidden from the public.

The Early Bombsight

All bombsights attempt to solve the problem of when to release the bomb—usually expressed as the range angle, the angle as measured between a vertical line through the aircraft and the line of sight to the target when the bomb is to be released. When the bomb finally hits the ground in 30 seconds or so, the effect of air resistance on the bomb means that aircraft will have already passed over the target. Finding that exact point in space to release requires knowing the airplane’s altitude, vectors of its speed over the ground, humidity, and the effect of air resistance on the bomb. Unpredictable factors such as local variations in gravity, air turbulence, and whether the target is moving also come into play.

All this information is difficult to determine accurately, particularly during the stress of combat, and it can change during the critical last moments of the bombing run. Pitch and roll of the aircraft and evasive maneuvers further complicate matters.

The first operational bombsights appeared during World War I. Simple affairs constructed of sticks, they were not much better than guesswork and a pilot’s good eye. They were of the timing type, so called because the bombardier determined the airplane’s speed over the ground using a watch. Then, using that speed, along with altitude as determined by the barometer and bomb type as data for ballistic tables, he would set key values in the bombsight. When the target below lined up in the sight, he would release his bombs. To eliminate sideways drift, the pilot would try to fly into the wind, but this tactic exposed the bomber to ground fire for longer periods. The pitching and rolling of the aircraft, as well as inaccuracies in release time and altitude, meant that the timing method was rarely accurate.

Later bombsights such as Norden’s were of the synchronous type, in which a motor in the bombsight slowly rotated a mirror in the sighting telescope’s light path to cancel out the apparent motion of the ground due to the speed of the bomber. Thus, when the bombardier looked through his telescope, the ground appeared stationary. In principle then, all he had to do was keep the target in the center of his field of view and wait until the bombsight sensed that the aircraft was at the release point. Bombing runs could then be much shorter, often less than a minute. In practice, the method stretched the technology of the time, and while it gave better results than timing sights, it still was by no means as accurate as military planners wanted.

Carl Lukas Norden: “Old Man Dynamite”

Carl Lukas Norden was born in 1880 in Semarang, Java, and soon became known as an exacting, brave, and trustworthy youth, if not also somewhat self-centered and abrasive. He was classically trained in mechanical engineering at Switzerland’s respected Federal Polytechnic Institute, where he met Nikolai Lenin, an equally self-disciplined and irascible student with other aspirations. After immigrating to the United States in 1904, Norden worked at several jobs, eventually landing at Sperry Gyroscope Co., where he worked for four years on shipboard gyroscopes. Unsurprisingly, he had personality clashes with Elmer Sperry, quit over a salary dispute, and struck out on his own as a consultant, founding the modestly named Carl L. Norden Company.

Norden, called “Old Man Dynamite” by Navy personnel, was difficult to work with. Contemporaries referred to him as “self-centered, impatient, domineering, driven, abrasive, a perfectionist … and of the highest ethical standards.” He saw himself as a designer, not an inventor, believing that only God could invent. His name did not even appear on the patent for his most advanced bombsight, even though he was clearly the inventor. Norden sought anonymity.

Early in the bombsight’s development, the Navy became concerned that the project was too important to be put in the hands of one person, especially one so irascible as Norden. They recommended that he take on a partner and suggested Ted Barth, who had been in charge of gas mask production in World War I. Norden did so, eventually selling out to him but staying on as chief designer. It was a good partnership, because Barth had the important business savvy and diplomacy that Norden lacked. Barth was also an aggressive promoter and was the source of many of the enduring legends about the Norden bombsight.

Norden chose the synchronous method for his bombsight, but the difficulties facing him were formidable. First, tiny errors in bomb release time or plane orientation could make the difference between a hit and a miss. Success meant hitting objects that are too small to see from the planned bombing altitude of 20,000 feet. The device would necessarily be very complicated, yet had to be simple to operate and repair, highly accurate, robust under combat conditions, reliable, and need only a short bombing run from any direction relative to the wind. In addition, since an airplane in combat is an unstable platform, buffeted by air turbulence and antiaircraft fire and subject to evasive maneuvers by the pilot, the bombsight’s optics needed to be gyroscopically isolated from those unpredictable motions.

Like Thomas Edison, Norden disliked alternating current (ac) and impetuously required the use of direct current (dc) motors with their dirty brushes in his precision device. Further, his aversion to the new field of electronics led him to employ mechanical devices as the basis of his bombsight’s operation instead of faster, simpler, more easily manufactured, and more reliable electronic circuits. These biases unnecessarily complicated his bombsight design, introduced errors that curtailed accuracy, and resulted in maintenance headaches.

“The Golden Goose”

Carl Norden delivered his first production bombsight in 1939. Its performance during controlled demonstrations was excellent. In April, at Fort Benning, Georgia, four Norden bombsight-equipped Boeing B-17 Flying Fortress bombers targeted a simulated battleship 600 feet by 105 feet in size. Ten out of 12 bombs of various sizes hit the target.

On December 2, 1941, the acting chief of the Bureau of Aeronautics enthusiastically wrote to the secretary of the Navy, “The Norden bombsight is considered to be the principal single factor of superiority which the air forces of this country possess over those of potential enemy countries.”

However, as everyone was to learn, there was a big difference between superior results at demonstrations against fixed targets under ideal conditions and those during wartime. In addition, bitter internecine rivalries between the Army and Navy would create havoc in implementing the bombsight into the armed forces.

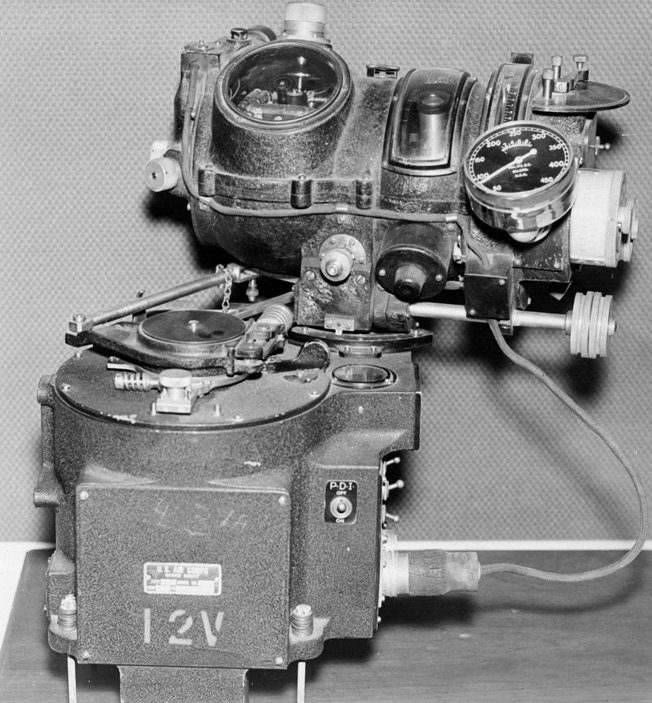

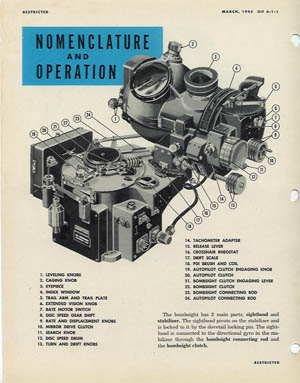

The Norden bombsight, later called the Mark 15 by the Navy and the M-9 by the Army Air Forces (AAF), weighed more than 40 pounds. It was an exquisitely complex, but ungainly looking two-piece instrument consisting of a sight head containing a telescope, a vertical gyro, and sighting controls, all perched on top of a stabilizer, an automatic pilot that let the bombardier fly the aircraft during the last portion of the bombing run.

A profusion of knobs, gauges, levers, windows, and indicators protruded from Mark 15’s lumpy frame. It was variously called “the golden goose,” the “cork and jug,” the “football,” and other less complimentary expressions. Inside were two high-speed, dc-powered gyroscopes, one for maintaining vertical orientation once set by the bombardier and the other in the stabilizer for azimuth, or heading. These maintained the target in the crosshairs, regardless of any buffeting or maneuvering of the airplane. The bombsight also had an automatic bomb release, since at a 200 mph cruising speed an error in release of only a half second would miss the aiming point by 150 feet.

Challenges for the Bombardier

Brigadier General Eugene Eubank called the bombardier “the most important of our fighting men.” The bombardier’s job was to enter various parameters into the bombsight and then perform a long series of fine-tuning adjustments leading up to the final automatic bomb release. His duty station was in the plexiglas nose of the aircraft, a very exposed position that led to a high injury rate. As a result, volunteers were few in spite of the favorable publicity and the patriotic 1942 Richard Rodgers tune, “The Bombardier Song.”

For the bombardier specialty, an airman went through up to 18 weeks of training, where the best of them attained the rank of distinguished bombardier. For short bombing training runs without any of the fear, smoke, and dust that he would encounter in combat, the average error required for this exalted rank was 172 feet. Yet, a bomb dropped that distance from many targets was unlikely to do any real damage, and standard performance under combat conditions was usually much worse than that.

One of the most vexing problems for bombardiers was reading the bombsight’s two bubble sights, mounted at right angles on the vertical gyro’s frame. Similar to those on a carpenter’s level, they helped level the bombsight in the vertical plane. However, trying to read them while the plane was vibrating, performing evasive maneuvers, and moving through turbulent air was a real challenge. To complicate matters, the size of the bubbles was affected by the widely varying ambient temperature.

Solving the bubble problem was essential because maintaining a level flight path was critical for bombing accuracy, and the bombsight’s gyro would keep the sight only as level as the vertical set by the bombardier. BuOrd unsuccessfully experimented with an electromechanical approach to performing the same function as the bubbles.

To Drop a Bomb

Hunkered down over his instrument, breathing pure oxygen, distracted by the roar of his bomber’s engines, fighter attacks, the impact of antiaircraft bursts, and the racket of his own plane’s defensive fire, the bombardier tried to read the fine print on his bombing tables and handheld computers, which were similar to a slide rule, to figure out various speeds, angles, and bomb ballistic parameters. Then, he peered through the telescope at the target, often partially obscured by clouds, haze, smoke, or fire, as he steered the plane to the release point, making dozens of last-minute adjustments. It was amazing that any of them hit anything.

There were dozens of preliminary steps to set up the Norden bombsight. One of the first was to level the gyroscopes using the bubble sights. Then, the time of fall for the bomb, proportional to the square root of altitude, was entered by presetting the altitude, which in turn set the speed of a motor driving a disk. Trail, the distance behind the plane that the bomb hits—caused by air resistance—was verified from bomb characteristic tables for the planned airspeed and was used to set the position of a roller on that disk. These two settings controlled the angular rate of the telescope mirror, which, along with the gyroscopic stabilization, kept the view of the ground stationary, a key characteristic of a synchronous bombsight.

The drift, or crosstrail, setting tilted the telescope view to compensate for the sideways motion of the bomber that was caused by crosswinds. Finally, the bombardier used his bombing computer to figure out and preset the dropping angle, the calculated bomb release point.

During the last minute or so of the bombing run, the bombardier used a series of knobs to fine-tune the preset values, canceling out both the forward-aft motion and sideways drift of the target in the field of view of his telescope and finally positioning the target so it was stationary, dead center in the crosshairs. After these settings were made, with the autopilot engaged and the gyros keeping all the mechanisms stabilized, the bombardier would then fly the aircraft the last few minutes of the bombing run. The ultimate purpose of the complex, interconnected array of motors, gyros, cams, levers, and cables in the bombsight was then to slowly advance a single indicator until it matched the predetermined dropping angle, at which time the bombsight would automatically release the bombs.

Accessories and Enhancements

As the war progressed and the needs of the AAF changed, a number of attachments were fashioned to improve the bombsight’s performance under various operating conditions without redesigning it. This was an attempt to achieve a universal bombsight that would handle the three important kinds of bombing missions: horizontal, glide, and dive.

These attachments included devices to perform bombing during a shallow dive or glide (GBA), thereby making it more difficult for antiaircraft gunners to get a bead on the bomber; a low-altitude attachment (LABA) to better suit the Navy’s needs for torpedo bombing; one to extend the Norden bombsight’s vertical range for the AAF; a reflex sight with improved optics for initially locating the target at night; and a “formation stick” so that the pilot could maintain position in formation by flying the autopilot, similar in effect to modern joystick controls.

There were also radar aiming attachments to overcome the adverse weather conditions in Europe and improve bombing through overcast conditions. Even though the radar attachments never resulted in an improved error rate because of the imprecision of early radars, the crews appreciated them since their chances of surviving a bombing mission flying through thick clouds were much improved even if their bombing accuracy suffered.

Another accessory was the intervalometer, a means of releasing bombs at a preset time interval so that they would evenly cover a large area. Without it, salvo bombing released all the bombs at once for a concentrated but not necessarily accurate attack.

A Complicated Design

The Norden bombsight consisted of more than 2,000 parts such as dc motors, gears, potentiometers, clutches, levers, cams, mirrors, gyroscopes, and specialized components such as gudgeon bearings, cardans, and gimbal rings. Some parts required machining to extremely close tolerances, previously unheard of in a mass-produced device. Typical of his imperiousness, Norden set aside no-smoking areas in his plants to help maintain dust-free conditions and yet violated his own rules by smoking cigars there. No one dared challenge him about it.

The Norden bombsights were such precision devices that parts were not always interchangeable, complicating field maintenance. Lack of skilled machinists was an ongoing problem. Key parts such as the 61 ball bearings were in very short supply, necessitating Norden to set up his own manufacturing plant for them. He even decided to train the workers himself on how to properly make bearings. That plant, the Barden Company (Barth + Norden), still exists. In one of history’s ironies, Barden is now part of the German FAG ball bearing group with headquarters in Schweinfurt at one of the factories that Norden’s bombsights helped repeatedly attack.

Serious maintenance problems were also caused by vibration of the aircraft, electrical surges, inadequate lubrication, wear, and the brushes for the dc motors that spread their carbon dust into sensitive bearings. The overall complexity of the bombsight and the government’s desire to maintain the tightest level of security made its maintenance a continuing problem and adversely affected bombing accuracy. In late 1944, up to 75 percent of some batches of Norden bombsights fell short of specifications, missing targets by 280 feet from an altitude of 20,000 feet when specifications called for 50 feet.

The frequent equipment failures and cold temperatures led to operational problems with the Norden bombsight. The temperature in unheated, unpressurized B-17s at bombing altitude was so cold that the AAF purchased electrically heated blankets for the bombsights to avoid the congealing of lubricating oils and the fogging of the optics. In addition, the complexity of the device, overcast weather conditions, danger from antiaircraft and fighter fire, cold, fear, and exhaustion all contributed to inaccuracy. Even when the bombardier involuntarily rose from his seat as the release point approached, accuracy was affected because of a change in the optical path.

Production and Acquisition Problems

The commencement of World War II forced the Norden Co. to convert from an engineering development facility making precision bombsights by the handful to a high-volume production operation. However, this goal was often stymied because of the complexity of the device and the many engineering changes. As a result, until late in the war, there was a desperate shortage of bombsights. To complicate matters, the Navy required the AAF to purchase bombsights only through them and controlled all contacts between the AAF and Norden, doling units out on an allocation schedule that favored their own needs. BuOrd violated numerous regulations in setting up Norden as a sole-source development and manufacturing entity, but the arrangement suited both parties; BuOrd got its bombsights and Norden had a reliable customer with a never-ending stream of production. Disputes arising from the unusual procurement arrangement produced reams of angry letters between senior officers of the two armed services.

In spite of the rivalry and Ted Barth’s exploitation of it to Norden’s benefit, it remains a puzzle why the Navy was so adamant about retaining control and satisfying its needs first when the Army clearly had the greater need and the Navy knew it was not using all the units it took. One possible explanation is that the Navy rigidly ordered bombsights and spares for all bombers on which the bombsight was standard equipment, whether needed or not, and bureaucratic inertia prevented the Navy from changing policy. This was in spite of the much greater need on carrier-based missions for dive bombers, which had proven the most effective type of bomber against moving targets. The Norden bombsight was unsuitable for dive-bombers because of the rapidly changing altitude.

A Marketing Success, an Understated Legacy

During World War II, Norden (and its subcontractors, some of which were Norden subsidiaries) and the Sperry Gyroscope Co. were the major suppliers of bombsights to the American armed forces. Sperry had been encouraged by the AAF to develop a bombsight for them that would make the AAF independent of the Navy and its Norden sight. Their sight, by Sperry, which first saw combat in 1941, had a number of important engineering advances that should have made its performance and maintenance superior to the Norden unit, but it never lived up to its promise. Also, its decade-long head start and Ted Barth’s promotional ability had fully entrenched the Norden Company’s business position with the military hierarchy.

Further, the key people in the Sperry project for both the company and the AAF were killed in separate accidents, and Sperry’s extensive prewar involvement with companies in both Germany and Japan, including having sold a bombsight to Japan in the 1930s, did not help its position as a supplier of such a sensitive apparatus. Finally, having two such extremely complicated, competing devices created intractable logistics and maintenance problems for the armed services. So, in 1943, after extensive performance tests and intense lobbying by both sides, and less than one year after Sperry’s plant began producing its S-1 bombsights for the AAF, Washington decided to standardize on the Norden unit and shut down the Sperry operation.

During the war, Sperry maintained complete silence about involvement in the bombsight business. Even today, its bombsight involvement is described on its website as having made “other instruments for aircraft.” In contrast, the mystique that surrounds the Norden bombsight is a direct result of the unrelenting publicity effort maintained by the Norden Company.

Keeping the Lid on the Bombsight

As a result of its early successes in demonstrations, the Norden bombsight was highly classified. Although its existence and accuracy were heavily publicized to help boost morale, its details were a closely guarded secret. Since it was one of this country’s most important military secrets, no photographs or release of specifications or performance data to the public were allowed. Several popular publications of the day did run articles on the Norden bombsight, although for the most part their attempts to describe it were wrong or sketchy.

To maintain the secret, Washington developed an intricate and highly secure system for shipping and handling the Norden bombsight. However, these handling procedures made efficient maintenance almost impossible and greatly complicated flight operations. The unit had to be kept covered except when in use, have armed guards escort it to and from the aircraft, and required the use of bombsight storage vaults between flights. There was even a much ballyhooed bombardier’s oath, with pledges to kill oneself in the event of its imminent capture. Regulations called for destroying the unit with a bullet in its guts, immolating it with a blowtorch-like device, or ripping it out and tossing it overboard.

Secrecy was broken when a Norden Co. employee named Hermann Lang stole the plans for the Norden bombsight, for which he was paid a reported $1,500 by the Nazis. This event must have rattled Norden, who held Germans as untrustworthy and yet employed numerous craftsmen of German descent in the manufacture of his bombsight. In June 1941, the FBI arrested Lang and 28 others on spying charges. Lang was found guilty of espionage by a Brooklyn, New York, district court jury on December 13, 1941, and sentenced to 20 years in prison. He was released in 1950 and deported.

Eventually, the Norden bombsight was downgraded in classification due to difficulties in field maintenance, the large numbers of people involved in its production, and the knowledge that the Germans had recovered bombsights from crashed aircraft. In November 1944, it was finally publicly displayed. The secret was out.

The Norden Bombsight in Strategic Bombing Doctrine

The Germans had their own bombsight, named the Lotfernrohr, or Lotfe. Like Norden’s, it was of the synchronous type and had even more elaborate optics. However, captured Lotfes were judged inferior to the American bombsights, and the Germans never used Norden’s stolen design. Since they had decided to concentrate on dive-bombing as tactical support for ground attack, precision high-level bombing was not an important part of German war doctrine. Japan never had a bombsight as sophisticated as any of the Allied units, and Japan’s need for high-altitude bombing of Allied targets was minimal. (Read more about the weapons and machinery Allied and Axis powers developed in the 20th century inside the pages of WWII History magazine.)

The actual performance of the Norden in combat was good some of the time, but rarely great, and often terrible. Several studies revealed that as few as 5 percent of Eighth Air Force bombs fell within 1,000 feet of the target and the average error for 500-pound bombs dropped in Europe was a whopping 1,673 feet. There are examples of many hundreds of bombs aimed at a single small target with only one or two bombs reaching their mark. Some gross errors were even measured in miles.

Lack of accuracy was an important shortcoming because precision bombing doctrine called for being able to hit targets as small as tennis courts. With a delayed fuse, the 500-pound bomb could blow a crater only some 20 feet in diameter, whereas the bombsight’s error was almost always much larger. Direct hits or massive bomb loads saturating an area were required to accomplish the mission.

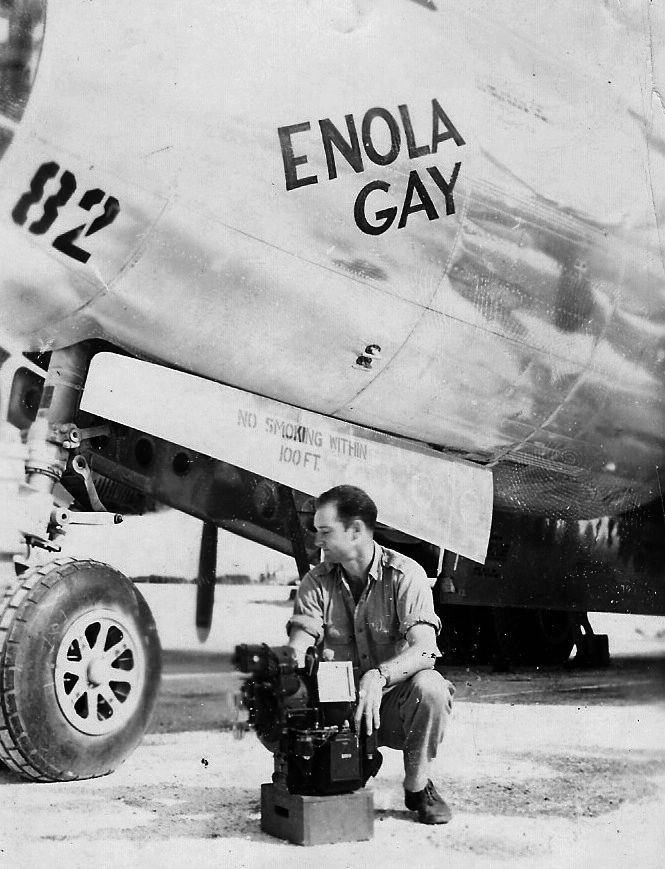

When the Boeing B-29 Superfortress bomber Enola Gay left the island of Tinian in the Pacific with its top-secret nuclear weapon, Major Thomas Ferebee, the 24-year-old bombardier, used a Norden sight, serial no. V-4120, to aim his bomb from 31,000 feet above Hiroshima. He was 800 feet off his target, but the destructive force of the atomic bomb was so great that it made no difference.

Three days later, Captain Kermit Beahan, the bombardier of the B-29 Bock’s Car, dropped a bomb on the Mitsubishi Steel & Arms Works in Nagasaki. It was off the mark by 1,500 feet, a small fraction of the destructive radius of the weapon. Thus, with such powerful weapons, the accuracy of the bombsight was less critical.

Bombsights After the War

In successive conflicts, bombsights continued to improve in accuracy and reliability, with radar and other positioning means and with electronic controls instead of Norden’s mechanical devices. Simple gravity bombs are still being used for some missions. Yet, even today, in spite of all the technical improvements in bombsight design, they still suffer from the same inaccuracies for the same inherent reason—aerodynamics.

During the Gulf War, Coalition forces dropped some 17,000 precision-guided munitions with mostly pinpoint accuracy, but also 210,000 conventional bombs that missed their targets by an average of more than 300 feet, faring no better than many World War II-era bombs. It was only with the advent of guided munitions that pinpoint accuracy has been achieved. The unknowable variables of bomb aerodynamics and atmospheric conditions ultimately affect the ability to hit the target with an unguided gravity bomb.

Even with its faults, the Norden bombsight was a technological marvel for its day. In spite of its many shortcomings, it did help bombardiers achieve the strategic objective of destroying the enemy’s infrastructure. What it did not do was meet the planners’ unreasonably high expectations for accuracy.

During the Mark 15 Norden bombsight’s long history, the U.S. government purchased more than 50,000 bombsights. By 1944, the typical unit cost was about $7,500. However, the cost of the entire program came to more than $1 billion. The last combat use of the Norden bombsight was in 1967, when it was used for dropping acoustic sensors along the Ho Chi Minh Trail in Southeast Asia. Today, the Carl L. Norden Company’s role in bombsight development is consigned to history. The company lives on as the Norden Systems Division of Northrop Grumman Corp., making a variety of military avionics systems but no bombsights.

Interesting article. There are some facts that bear mentioning though. Many lead bombardiers actually trained their sights to drop short of the target that way the whole formations bombs would ‘walk’ into the target the goal being hit the target not impress people. This could account for a some of the bombs falling off target.

I would argue though that managing to land an average of 32% of your unguided bombs within 1000 -1600 feet of the target with an analog computer while dealing with uncooperative weather while being shot is quite a feat to be honest.

What others also over look is that after the Mustang was introduced the goal shifted to luring the Luftwaffe into battle and destroying their planes. Bombing factories became somewhat secondary. On that I think we can all agree it was successful

I think I read in Ian Toll’s account of the Hiroshima bombing that the device detonated 550 feet from the target. That would be like seven houses down from mine if they were aiming at my house. And with the detonation occurring at 1800 feet, not sure how they could determine with a high degree of accuracy where the bomb would have actually landed if it had gone all the way to the ground. Of course the 509th was highly trained and the cream of the crop of the USAAF, and I would think that a five ton bomb wouldn’t be affected by winds, but still very impressive from 31,000 feet for an unguided bomb.

CD Bauman is quite correct though as are many of the critics. Although not a significant part of the overall action, a flight of B 17s from Midway Island tried bombing the attacking Japanese fleet about 200 miles out and scored not one hit. It did serve a purpose as Admiral Nagomo ordered the carrier planes re-armed with bombs instead of torpedoes so they could destroy the Midway Airfield. This delay enabled the American carrier fleet to locate and destroy three Japanese carriers that day and a fourth in the evening. The next day, Adm. Yamamoto ordered a withdrawal.