By Albert Mroz

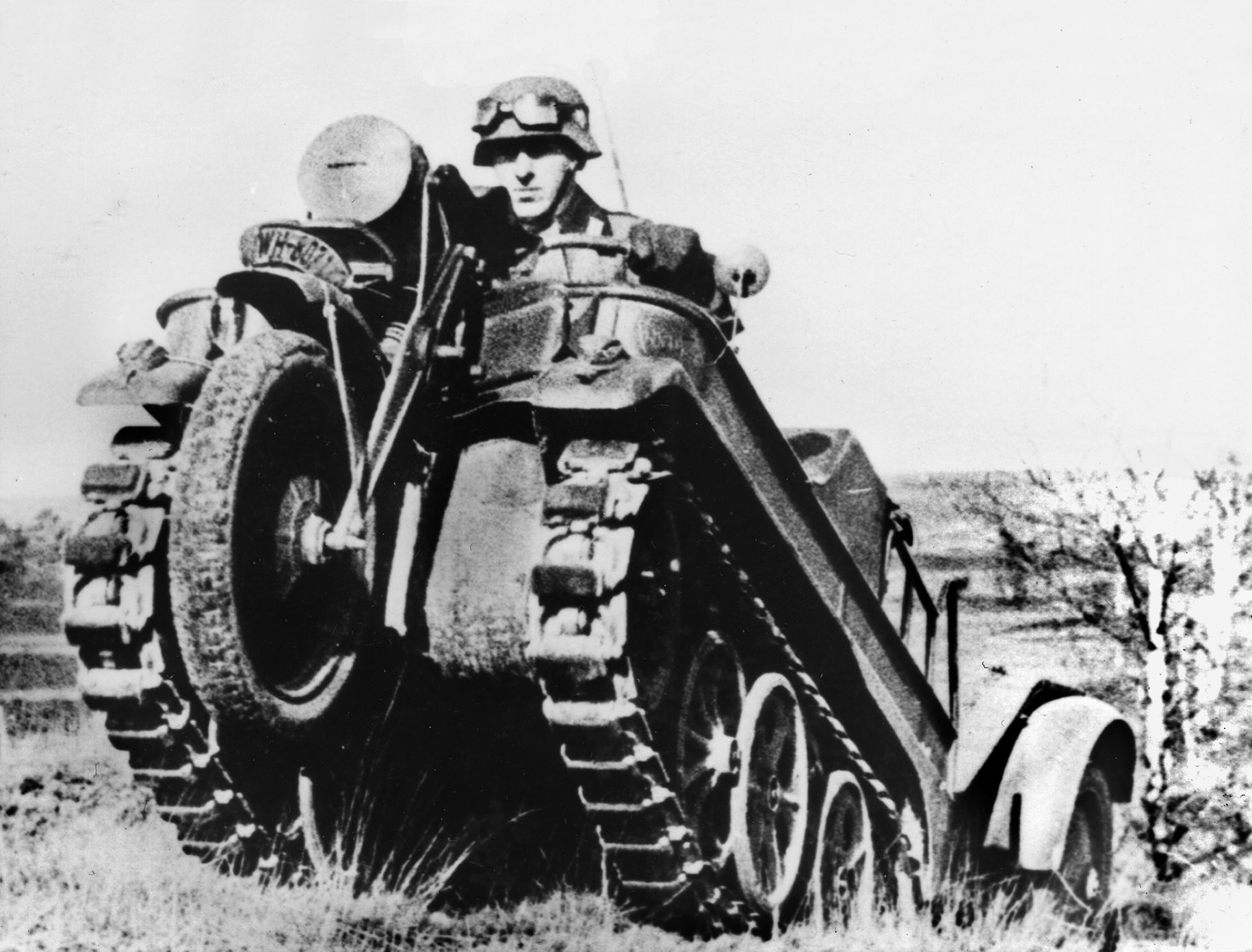

Aside from a number of prototypes and experimental vehicles, the Kettenkrad was one of the most unconventional vehicles built during World War II. It was officially known as Sonder Kraftfahrzeug Kettenkraftrad, or “special road vehicle half-track motorcycle.” The Kettenkrad was a utilitarian, compact vehicle that lent itself to a number of off-road or towing applications. The limitations of its success lay more in execution than in basic concept.

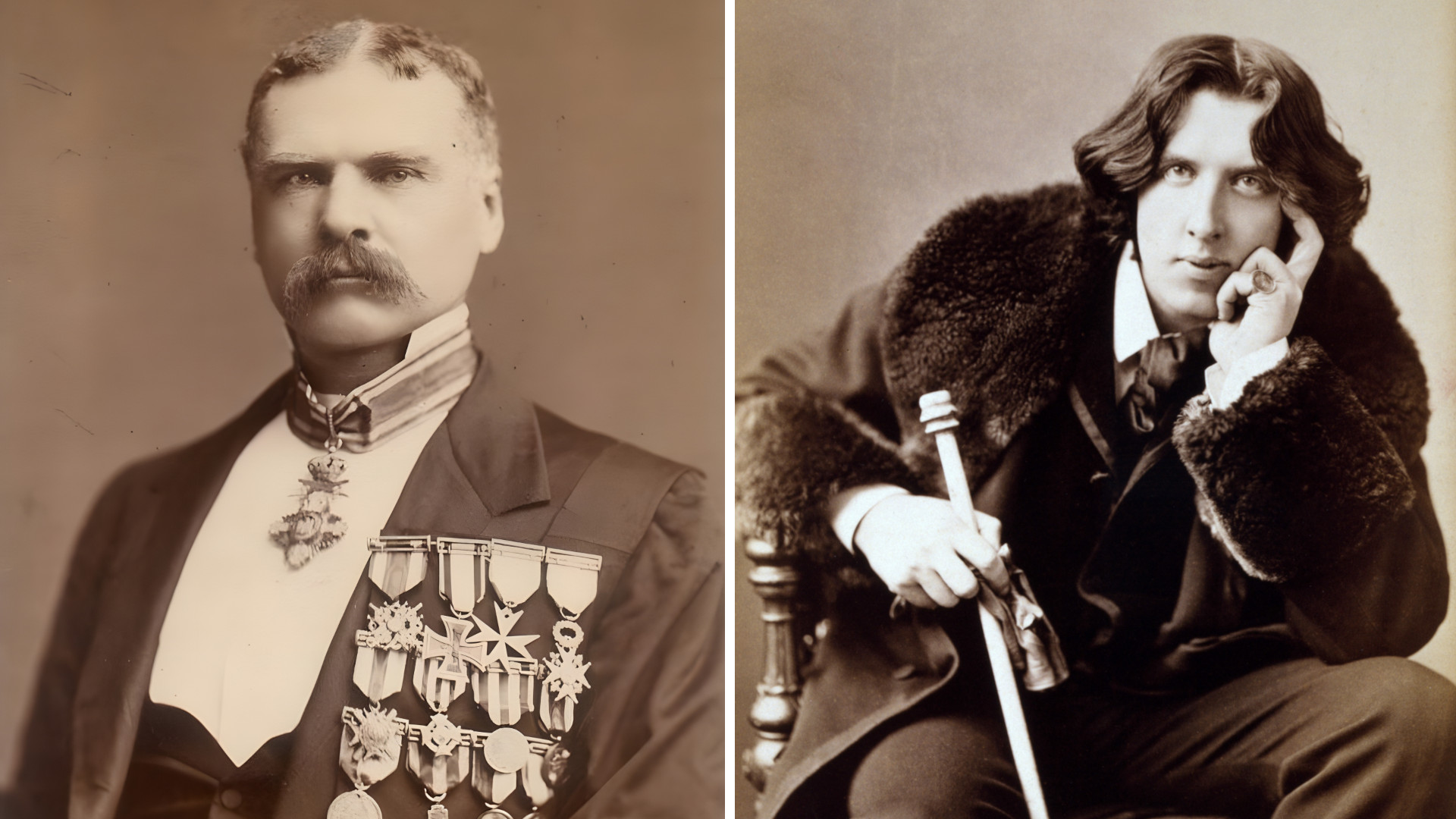

Although the front fork of the Kettenkrad had a steering function, the essential mechanism of the vehicle was in its transmission and differential system, which required a high degree of sophistication in manufacturing, especially in metallurgy and machining of gears. Despite ancient references going back thousands of years to the time of chariots, the modern vehicle differential was patented in 1827 by French watchmaker Onesiphore Pecqueur. This was the era when steam-powered transport was being extrapolated to function on the ground without rails, and the friction encountered by the drive wheels required a compensation of rotational speed when a vehicle made a turn so that the outer wheel could turn faster than the slower inner wheel. In 1832, Englishman James Roberts called his invention “the gear of compensation” for use in “road locomotives.”

In 1876, James Stanley of Coventry invented the chain-drive differential, a design that was used only for a few years by Karl Benz in what is considered to be one of the world’s first gasoline motor vehicles; the other early vehicle was built by Gottlieb Daimler in Germany. Further improvements included the use of spiral bevel gears to reduce noise, which were introduced in 1913 by Packard for mass production, as well as hypoid gears, using hyperbolic shape rather than simple conical spiral bevel, which began to be manufactured in 1926, also by Packard.

In 1940, after World War II exploded in Europe, German motorcycle manufacturer NSU was commissioned to build a small tractor. Located in Neckarsulm, NSU had already begun designing a light tractor in 1938. Inventor Heinrich Kniepkamp received a patent on June 29, 1939, for small half-track vehicle. NSU adapted as many motorcycle parts as possible, which included front fork, motorcycle wire wheel, seat, instruments, handlebars, and a 600cc motor. All but the instruments, headlight, seat, and handlebars proved inadequate in the final version. The first 70 of the finished NSU vehicles were delivered later that year.

Some early tracked vehicles such as the Holt used a design with a steerable front wheel. The steerable front wheel was abandoned during World War I, when tanks went through a design evolution that adopted much better steering control by effectively separating the power to each track using a differential, thereby steering the vehicle more accurately and allowing the tractor to turn within a small radius the width of the vehicle.

The mechanism for this type of control was often referred to as the Cletrac braked differential. It was the essential mechanism for steering tracked vehicles not using any steerable front wheels. Cletrac was the trademark name of the Cleveland Motor Plow Company, which was founded in 1916 by Rollin H. White and Clarence G. White. Until then, the conventional method of steering a tracked vehicle was to disengage one track or the other to make a turn. This meant losing traction. Cletrac used a planetary transmission controlled by a brake at each drive cog, which provided controlled power to each track without declutching.

Because the front wheel would leave the ground on uneven terrain even at slow speed, it meant declutching one track or the other to steer just when traction was most vital. If the front-wheel lifted off the ground, which was a common occurrence for any off-road vehicle of this type, front wheel steering was rendered inoperable. The Kettenkrad was capable of 50 mph at 4,000 rpm of the engine, so the front motorcycle fork-and-wheel were intended for steering at a considerably high speed for a tracked vehicle, although the top speed was possible only on level road. According to the operating manual, the recommended top speed was 38 mph at 3,000 rpm.

Kettenkrad’s maximum carrying capacity was 3,250 pounds, while the designed axle load on the front wheel was 120 pounds. Moving the handlebars in either direction more than five centimeters (approximately two inches) activated the steering brakes. This allowed for gentle turns without brake steering. The gear-shift lever was mounted between the driver’s legs, while engine speed was controlled with a handlebar control grip. While the driver sat on a standard motorcycle seat, the clutch and brake were operated by foot pedal. This demanded an amalgamation of skills combining motorcycle- and automobile-driving coordination. The problem was that the Kettenkrad was too narrow for its speed capabilities in relation to its center of gravity.

The Kettenkrad’s differential used spur gears. To control each track for steering, an internally expanding brake was used for each side. The drums were not fastened directly to the axles, but instead were driven from the differential spur gear pinions at higher speed through a set of gears for higher efficiency. The transmission had an Opel multispring, single dry-plate clutch mounted on the flywheel in conventional fashion, with three speeds forward and one in reverse. Additionally, an auxiliary high-low gearbox was incorporated. The entire arrangement was controlled by a long gearshift linkage and lever held in front within an H-shaped opening at the dashboard. To prevent accidental shifting into reverse, a hinged latch covered the gate.

Steerable wheels at the front of a tracked vehicle did not make for easy control, and this was also known to be true for larger half-tracks, especially without using a declutching or planetary differential. Half-tracks with two wheels in front had a reputation for being very stubborn vehicles to steer, on any type of surface. The front wheel of the Kettenkrad was designed to be removed for off-road conditions because the propulsion of each track of the vehicle could still be controlled separately for steering by left and right movement of the handlebars, which controlled the individual track speed. However, removing the front wheel greatly limited top speed on any road course.

Stability on rough terrain was one of the basic essentials for any good tractor, and this important feature needed to be balanced with adequate ground clearance. These two design elements have always been at odds with each other, and one solution to the problem has been to make the tractor wide enough to help with stability to prevent rollover. The Kettenkrad was a narrow vehicle, which made it much more maneuverable and nimble but also made it prone to rolling over, especially on a side slope.

The fact that many of the Kettenkrad’s components were too flimsy became apparent only later through attrition in the field. One problem was that the tracks were designed to be more complex than they needed to be. Every link, of which there were 80, was designed to interconnect with a precision pin rotating inside a pair of needle bearings. Each link had a hollow guide hole as a grease point, and the vehicle required lubrication of all needle bearings and pins every 1,200 miles. This job could take hours—not a practical operation in a war zone.

The front fork tended to break, so it was first beefed up, then eventually replaced in 1942 by an entirely new unit with a hydraulic shock absorber. The wire wheel was also replaced early on by a single-piece disc wheel. The overall width of the Kettenkrad was 100 centimeters (just under 40 inches), which made it unstable and prone to roll over. This was exacerbated by the weight of the substantial water-cooled four-cylinder engine, which was a 1,478cc, 36hp Opel unit adapted from earlier Opel Olympia Model 38 automobiles after the 600cc motorcycle engine was deemed inadequate due to lack of horsepower and possible overheating. The vehicle had a three-speed manual transmission with reverse and a 75-watt belt-driven generator, as well as a two-speed transfer gear box for two ranges, providing six speeds forward and two in reverse.

In low range, the vehicle could crawl at one mile per hour. Reverse was used for recovering other wheeled vehicles stuck in terrain. At cruising speed on the open road, the Kettenkrad delivered up to 17 miles per gallon using two tanks with a nine-gallon capacity. It could ford still water to a depth of one foot, seven inches. Without a trailer, the Kettenkrad could climb a 24-degree grade, but only half that with a trailer attached.

A fully loaded Kettenkrad could weigh as much as 3,470 pounds and still be kept within manual-specified load limit. In addition, it was designed to pull a 1,000-pound trailer. In low range, the Kettenkrad would sometimes tow several trailers, exceeding the factory specs in wartime conditions. One advantage of the size and weight ratio was that it had a ground pressure of only .61 kilograms per square meter. The vehicle’s carrying capacity of 325 kilograms (780 pounds) meant that three men with equipment qualified as maximum capacity—another combat environment shortcoming.

The Kettenkrad was first put through its paces on the Eastern Front during the Nazis’ first winter offensive in 1941. There, the Jagerstruppe (infantry) and Gebirgstruppe (mountain forces) would quickly find that the Kettenkrad was ideal in snow and forest conditions for towing light antiaircraft, antitank, and infantry guns as well as mortars and machine guns, in addition to pulling equipment trailers and carrying officers. The Fallschirmjager (paratroopers) also found the Kettenkrad very useful.

Originally, the Kettenkrad was used for laying field communication cable by the Nachrichtentruppe (signal corps). For this use the vehicle was well endowed, and wartime photos show just such activity. Perhaps because of its superficial resemblance to a motorcycle, the Kettenkrad was also expected to assume many other roles during World War II. It was used in terrain varying from snow-covered mountains in Finland and Russia to dry deserts in North Africa, serving the functions of reconnaissance officer’s car, recovery vehicle, ammunition carrier, personnel carrier for POWs, trailer, and gun and aircraft tow vehicle. Toward the end of the war, the Kettenkrad towed Me 262 jets as German airfields became increasingly makeshift.

For tropical areas, the vehicle was only slightly modified. The oil filler cap had a linen hood, and the cooling fan was driven 1.4 times faster. Instead of the Opel carburetor, a Solex unit was used that was equipped with an oil-bath air filter with precipitator. The starter had a solenoid instead of a mechanical actuator, and a larger generator was used. Linen hoods also sealed the transmission levers, and tracks had extension plates welded on for use in loose sand or swamp. Track brakes had covers welded on to minimize sand entry. The twist throttle grip was also sealed with linen at each end, but loosely enough for rotation. A gasoline can and water can were included in the tropical version, along with a 20-foot wire and tarp for camp.

Other upgrades included more substantial transmission housing, heavy-duty six-spoke idler wheels, mudguards, and a variety of cooling vents. For all its versatility and maneuverability, the Kettenkrad had a weakness in its steering brakes, which suffered oil contamination from a steering mechanism that was insufficiently sealed. This, in turn, resulted in the failure of the track steering system. Both steering brakes had small drain pipes for the oil to escape. NSU engineers knew of the problem but were unable to resolve it in the vehicle’s short life span.

NSU also built a five-seat variant of the Kettnekrad with a six-cylinder Opel Kapitan engine. Only 10 prototypes were ever built. There was also a wider radio-controlled version intended for use as a mechanized bomb vehicle. This version was called Mittlerer Sprengladungstrager Springer, and 50 were built, but only three saw any combat action. In all, at least 8,025 Kettenkrads were built during the war, including 4,490 in 1944 alone. About 500 were built after the war as forestry tractors, with NSU continuing production until 1948. In France, the Babiole Company converted a number of captured Kettenkrads to be used as vineyard and orchard tractors because they were narrow enough to fit between trees and lines of grapevines.

Metallurgical advances and material availability after the war allowed for the manufacture of sturdier transmissions, which were a big improvement over the flaccid earlier production units. With all its teething under extreme conditions, the Kettenkrad would finally emerge as a highly versatile and potent vehicle. But like many war machines, gradual and expensive design evolution, along with changing conditions, would also lead to its extinction. Nevertheless, the Kettenkrad served as an inspiration for many new designs, including small, four-wheel, all-terrain vehicles (ATV) and a new generation of fast ATV-tracked vehicles now being developed for all types of off-road applications.

Join The Conversation

Comments

View All Comments