By Allyn Vannoy

The Time magazine article was titled “It Flies!” It was a note of triumph and vindication, but also an epitaph, of an aircraft that was five years in the making—the “Spruce Goose,” a plane that should not have existed. Many things were against it, even, to a certain degree, its creator.

The week of May 4-10, 1942, saw the loss of 300,000 deadweight tons of Allied shipping to German U-boats, loss rates that were twice new ship launches. Imaginative use of America’s industrial and technological strengths to deal with such problems was the mission of the War Production Board’s planning committee.

On May 22, F.H. Hoge, Jr., a member of the committee, proposed the use of extremely large flying boats, pointing out that current aircraft on transoceanic flights devoted 38 percent of their takeoff weight to fuel and oil, but that a 300,000-pound plane would use only 20 percent, and, that since flying boats did not require landing gear, an additional 15 percent in aircraft weight would be saved.

But it was the industrialist Henry J. Kaiser who saw the opportunity. He approached such problems with big schemes, limitless energy, and a genius for organization and improvisation. He had moved from constructing mammoth hydroelectric dams, such as the Hoover and Grand Coulee, to shipbuilding in 1941.

Faced with the terrible loss of shipping that was threatening the Allies, Kaiser suggested two possible solutions. One was to convert some of his shipyards to the mass production of giant seaplanes. The other was to mass produce antisubmarine aircraft carriers on Liberty Ship hulls. In the latter case, Kaiser facilities would produce some 70 escort carriers during the war.

But in the summer of 1942, after the Germans sank 681 Allied ships in the first seven months of the year, the idea of flying boats captured the nation’s imagination. In July, Kaiser outlined plans for flying boats of 200 to 500 tons and launched a publicity and lobbying campaign telling the press that he envisioned a fleet of 5,000 flying boats.

He followed with a proposal to the Army and Navy. And, though they considered it impractical, they knew that the public and some members of Congress believed otherwise. The Aircraft Division of the War Production Board was asked to review Kaiser’s proposal.

Merrill C. Meigs, deputy director of the board’s Aircraft Division, told Kaiser that it took more than four years to develop a new aircraft, but Kaiser was undaunted. Regarding possible resource requirements, Kaiser said he would build a steel foundry and educate and develop technicians and engineers in support of his proposal.

Meigs then set up a committee of aircraft manufacturers to hear Kaiser’s plans. But the manufacturers were not enthusiastic about the possible entry of another aircraft company into their industry. Donald Douglas, head of Douglas Aircraft, advised that to prepare a preliminary design for a 200-ton aircraft would require at least 100,000 engineering hours.

During July and August, Kaiser made two proposals—mass production of the Martin Mars flying boat and the design and development of the 200-ton flying boat––both taken under consideration by the War Production Board, headed by Donald Nelson. The Mars, first flown in June 1942, was a four-engine, 200-foot wingspan, 75,000-pound aircraft capable of carrying a 32,000-pound payload, or 133 troops, over a range of 5,000 miles. But Nelson was concerned about the possible impact on existing programs by manufacturers working at full capacity.

Kaiser then approached the well-known aviator, Howard Hughes, with a pitch to jointly develop the large flying boat. Though aware of the problems in designing a new aircraft, Hughes was intrigued with the possibility of coming up with the world’s largest airplane, especially after being told that the Douglas, Martin, and Northrup aircraft companies all thought that it couldn’t be done.

By August 22, 1942, after several weeks of discussion, a handshake agreement was reached—Hughes would design the plane and Kaiser would build it. Subsequently, a written contract between Hughes and Kaiser called for the design and construction of 500 aircraft.

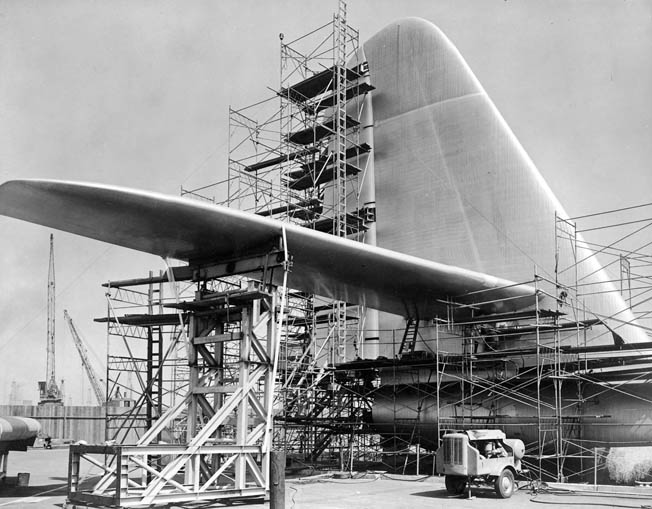

The Gigantic Spruce Goose

On September 17, Kaiser-Hughes received authorization to proceed with design engineering and construction of three prototype flying boats. Among the conditions imposed were that all construction would use a minimum of any critical or strategic materials, that no engineers or technicians working for manufacturers already engaged in the war effort could be employed without the permission of their employers, that they could spend no more than $18 million, and that the program would be limited to 24 months. But the Kaiser-Hughes partnership soon dissolved and Hughes proceeded alone. During the first seven months of the project, Hughes acted as general manager. Kaiser, unsuccessful in his attempt at combining forces with Hughes, had nothing more to do with the project except to help out with providing a few personnel.

Design presented several challenges— such a plane would require an overhang wingspan 50 percent greater than the Martin Mars, which would present new torsional, wing flutter, vibration, deflection, and control problems never before tested.

Seven aircraft configurations were drawn up, including twin-hull and single-hull designs with four to eight engines. Hughes settled on a design gross weight of 400,000 pounds. This number was reached based on creating the largest aircraft possible using eight of the largest engines then under development. Eight was considered the maximum number of engines that seemed practical.

In the final design, the HK-1, as it was called, would be built mostly of wood, its elevators and rudder fabric covered. It was referred to as the “Flying Lumberyard” by critics, while Hughes detested the other nickname, “Spruce Goose.” To him she was “The Flying Boat,” though one story was that Hughes’s nickname for the plane was the “Jesus Christ,” since those were the first words out of the mouths of individuals when Hughes took them into the hangar where the plane was being built.

The giant airplane was made mostly of birch, not spruce, with a wingspan of 320 feet, a vertical fin of 85 feet, and a weight of 300,000 pounds. It was designed to carry 120,000 pounds of cargo, or 750 combat-ready troops, or two Sherman tanks. Its eight massive engines, with 17-foot propellers, generated over 3,000 horsepower each. It was to have a range of 3,000 miles at a speed of approximately 200 mph.

The Project That Wouldn’t Die

During the design phase, Hughes was rarely seen by other members of the team. He was a night owl, had a penchant for secrecy, and was involved in multiple simultaneous projects, as well as a reluctance to delegate authority. Key decisions were delayed for days in some cases because of problems contacting Hughes. Even as the project began to fall behind schedule, Hughes refused to relinquish control. He continued to be involved in the smallest of details but then would disappear for weeks.

Despite Hughes’s management style, some progress was made during 1943 on the aircraft’s design, but major problems resulted from combining wood construction with the plane’s giant size. Elaborate and costly jigs had to be devised and new glues and gluing processes developed. Development of new tools, materials, and methods was by trial and error, consuming time, material, and money.

Years later Hughes partially blamed delays on the requirement that he build the plane of nonstrategic materials; however, government records indicate that Hughes was given the option of switching to metal, but declined. Given the progress that had been made in pioneering innovative methods in wood construction, and Hughes’s attraction to the smooth finish of the Duramold plywood used, he was reluctant to change materials. Hughes was meticulous regarding materials, workmanship, and appearance.

Numerous elements lined up against the project. In October 1943 the Aircraft Production Board proposed cancelling the contract because it offered no useful contribution to the war effort. In early 1944 it was determined that successful development of the Mars flying boat would make the HK-1 unnecessary. In March 1944 the Cargo Plane Committee of the War Production Board was of the opinion that a change in the character of the war had abated a need for a giant cargo aircraft.

The War Production Board dispatched Grover Loening, seaplane designer and consultant to the board, to evaluate the plane’s design. But his report called the plane’s design amazing and the most remarkable flying boat he had ever seen.

On March 17, Hughes advised the board against stopping construction,saying, “If we are going to keep abreast of development in aviation, then we must reconcile ourselves to the necessity of building bigger and bigger airplanes.”

Despite the many efforts to kill the project, highly placed administration officials renewed it, though the plan was reduced to one plane.

At the same time that the HK-1 was under development, Hughes was also active in pushing development of the Lockheed Constellation—a postwar, four-engine transport and civilian airliner.

The First and Last Flight of the Spruce Goose

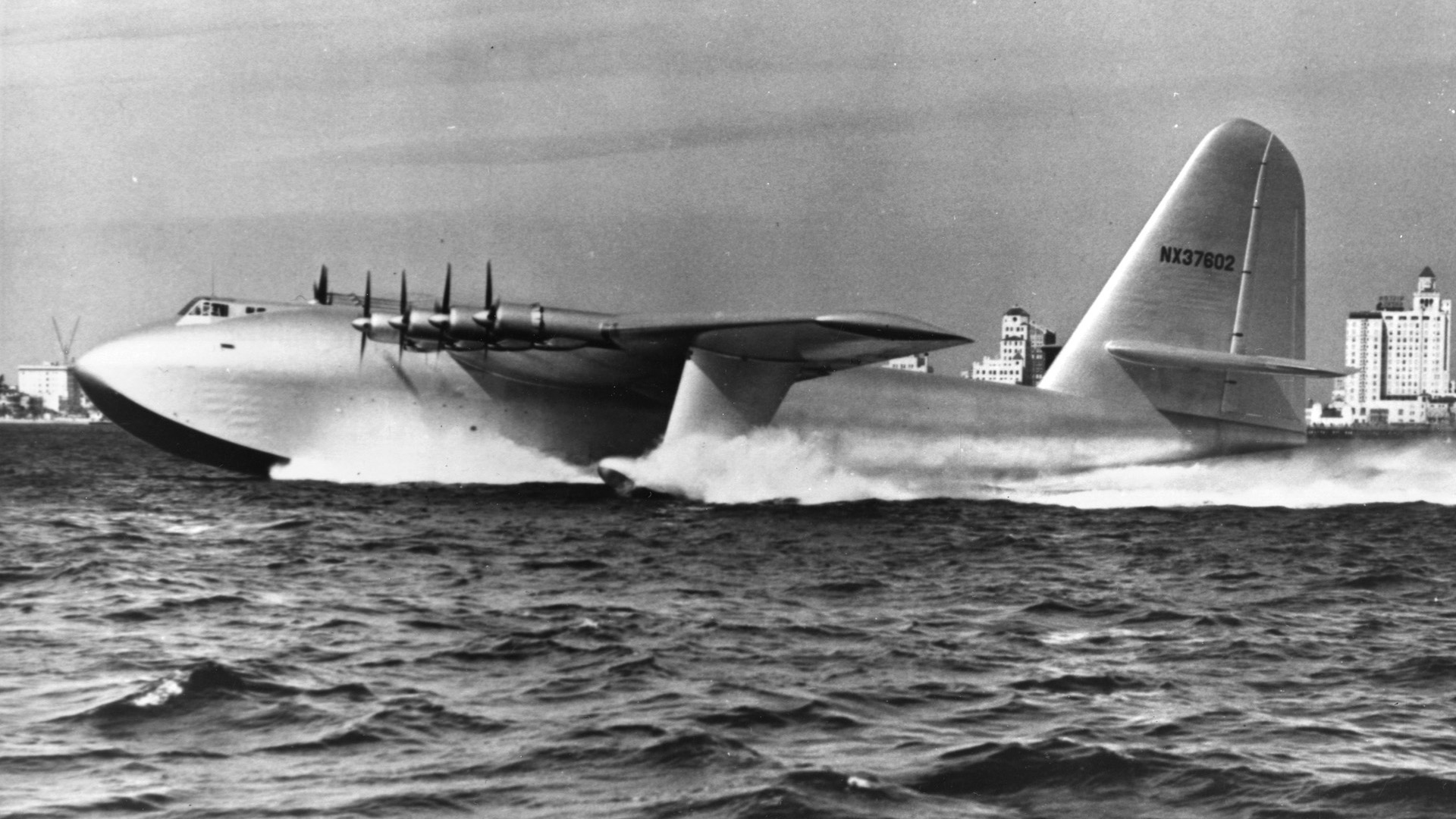

The project continued into 1947, when a Senate committee began investigating Hughes for defense contract irregularities. Hughes was called before the Senate War Investigating Committee in the late summer of 1947. During testimony Hughes stated, “The Hercules was a monumental undertaking. It is the largest aircraft ever built. It is over five stories tall with a wingspan longer than a football field. That’s more than a city block. Now, I put the sweat of my life into this thing. I have my reputation all rolled up in it and I have stated several times that if it’s a failure, I’ll probably leave this country and never come back. And I mean it.”

During a break in the Senate hearings, Hughes returned to California to run taxi tests on the renamed H-4 Hercules. On November 2, 1947, the taxi tests began with Hughes at the controls. His crew included Dave Grant as co-pilot, two flight engineers, Don Smith and Joe Petrali, 16 mechanics, and two other flight crewmen. In addition, the H-4 carried seven invited guests from the press and seven industry representatives.

After the first two taxi runs, Hughes made a third and surprised all the onlookers and crew as the Hercules lifted off, remaining airborne at 70 feet off the water at a speed of 135 miles per hour for around a mile. Having proven to his detractors that the aircraft was flight worthy, Hughes felt vindicated in the development of the aircraft and receipt of the government’s $18 million funding.

But the flight was not without concerns. Harry Kaiser, engine man, went down to the cargo deck after touchdown and saw the tail twisting around. Bill Noggle, hydraulic mechanic, posted in the tail, reported, “It’s about ready to leave us.”

After landing, Hughes was asked if he had expected to get the plane airborne. “Exactly,” said Hughes. “I like to make surprises.” Carl Babberger, Hughes’s chief aerodynamicist, stated, “All the factors were present for take-off—a high head wind, the 15-degree flap setting, and a light load. It probably got airborne before he expected it to, but on the other hand it wouldn’t surprise me that being under fire from Senator [Ralph Owen] Brewster, he was prepared to gamble. If it took off, fine. If it didn’t, fine.”

Several months after the test, through a spokesman, Hughes wanted it understood that the Hercules was only a research aircraft. That it would never be used in competition with military or commercial planes, but would help to deal with the problems of large aircraft—that the Hercules would point the way for big planes.

After the test a full-time crew of 300 workers, all sworn to secrecy, maintained the aircraft in flying condition in a huge, $1.75 million, climate-controlled hangar. A million dollars a year was spent maintaining the plane, as the engines were cycled and flight controls exercised weekly. Many modifications were designed and installed. For several years the crew expected that it would fly again as several more test flights were scheduled, then cancelled.

There was a great deal of speculation about why the aircraft was never flown again. Some said Hughes was afraid to, but his closest associates denied this.

The aircraft did have its weaknesses. According to one of Hughes’s mechanics, “Maybe one of the reasons why they didn’t fly it [again] was there was a little fluctuation in the tail, and maybe it wasn’t beefed up enough to suit him.”

But there was also no reason to continue the project because the need for big seaplanes had evaporated, especially an aircraft made of wood.

Even before the flight Hughes admitted that the plane was too large to be economical. However, claiming there were still research lessons to be learned, he stubbornly kept the work going. But he was distracted by other ventures and increasingly reclusive. After Hughes’s death on April 5, 1976, the plane was put on exhibit at Long Beach, California. In 1977, the U.S. Navy considered test flights with the H-4 as part of its research into low-altitude transoceanic flight, but never carried out the tests. The plane was moved from Long Beach to the Evergreen Aviation Museum in McMinnville, Oregon, southwest of Portland, in 1992.

Perhaps the key reason Hughes continued maintenance of the plane was that he saw it as his greatest aviation achievement. Despite being a short flight, the one and only flight of the Hercules may have been Hughes’s finest hour.

Join The Conversation

Comments

View All Comments